The system allows industrial users to monitor multiple compressors from a single controller without the extensive wiring traditionally required to connect multiple compressors to a master controller.

Bitzer twin-screw compressor with monitor

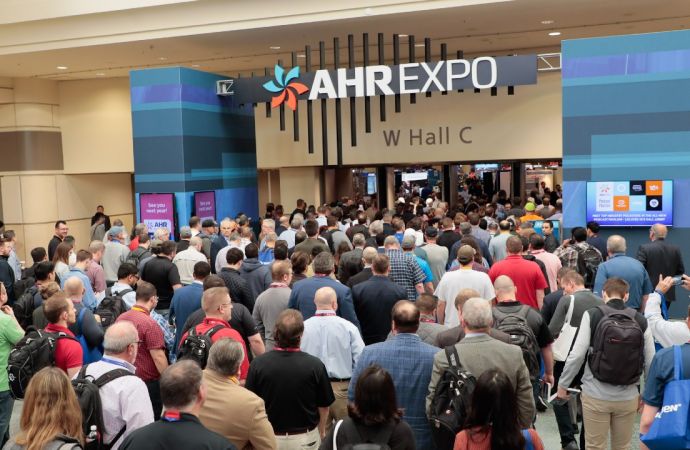

Refrigeration equipment manufacturer Bitzer showcased its largest industrial compressor as well as a new electronic monitoring system, the IQ Module, at the International Institute of Ammonia Refrigeration (IIAR) 2018 Conference & Expo in Colorado Springs, Colo.,in March.

The twin-screw compressor, which can be used with various refrigerants in applications of up to 300 tons of medium-temperature refrigeration, integrates an electronic monitoring system to facilitate operation, protection and maintenance, according to Joe Sanchez, director of engineering for Bitzer U.S., Inc, based in Flowery Branch, Ga.

“It’s a plug-and-play compressor,” said Sanchez. “We are integrating electronics into the monitoring of the compressor, so it makes life really simple for end-users, contractors and technicians.”

The monitoring system is currently available for compressors in the 150-TR to 300-TR range, but Bitzer plans to make the monitors available for smaller systems as well, said Sanchez. It’s applicable to various refrigerants.

We are integrating electronics into the monitoring of the compressor, so it makes life really simple for end-users, contractors and technicians.”

– Joe Sanchez, Bitzer US

The electronic monitoring system allows industrial users to monitor multiple compressors from a single controller without the extensive wiring that would traditionally be required to connect compressors to master controllers in multiple-compressor installations.

“All you need is Modbus communication, and you get all of the data for the compressor to a master controller,” said Sanchez. “This is really not done at the industrial level like this.”

The system includes a tool that allows technicians to access compressor data — such as alarms, trends, faults and other statistics — wirelessly via Bluetooth to facilitate service and maintenance.

At the IIAR conference, Bitzer was showcasing a simulator that demonstrated how the controller could monitor various analog inputs in an ammonia system.

“It is going to be a great diagnostic tool,” said Sanchez.

Related stories