Low-charge systems from Colmac Coil cut 18% to 38% in electricity usage compared to a traditional liquid overfeed system in study of cold storage facilities.

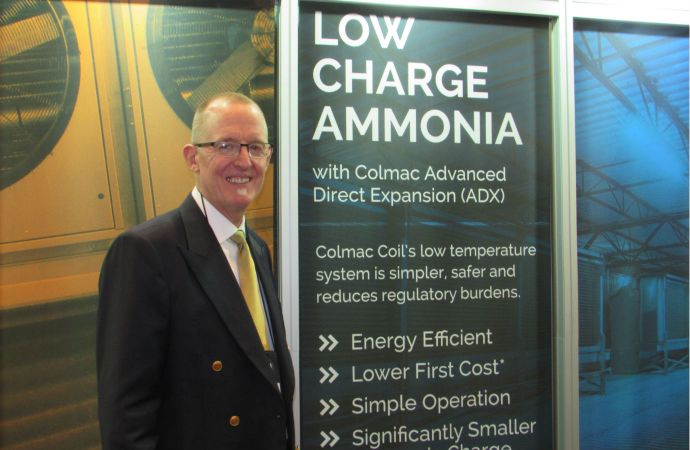

Bruce Nelson, Colmac Coil

In a comparison of two low-charge-ammonia DX systems to a traditional pumped liquid overfeed system in cold-storage facilities, the DX systems used 18% to 38% less electricity as well as far less ammonia, according to a presentation given at the Global Cold Chain Expo in Chicago in mid-June.

“On paper, we calculated that the [ammonia DX systems] would use 1.3% more horsepower per ton than a liquid overfeed systems,” said Rick Watters, vice-president of refrigeration group, AMS Mechanical Systems, Woodridge, Ill., which was the contractor for the ammonia DX systems. “But the bottom line is that the premium we thought was going to exist to do DX ammonia really doesn’t exist.”

The ammonia DX systems – both ADX (advanced direct expansion) systems made by Colmac Coil Manufacturing, Colville, Wash. – were installed at Joliet Cold Storage, Joliet, Ill., in 2014 and Liberty Cold Storage, Bolingbrook, Ill., in 2015.

Watters attributed the difference in energy consumption between the two ADX facilities to variances in blast freezing production. Both facilities also benefited from energy-saving technology like VFD motors on all fans as well as LED lighting.

The construction cost of the ADX system at the Joliet facility was $100,000 less than that of a liquid overfeed system, which uses a 3-1 ammonia ratio. “That was also the opposite of what was predicted,” said Watters.

In ammonia charge, the Joliet facility uses 8 lbs./TR; Liberty, 11.6 lbs.TR; and liquid overfeed, 72 lbs./TR. The Joliet and Liberty plants both deliver temperatures of -15°F and 20°F, and utilize thermosiphon oil cooling, low-charge condensers and stainless-steel piping. Joliet employs motorized TXVs, Liberty, pulse TXVs. Both use accumulators to capture liquid from the evaporators. “DX is theoretically dry suction back to the compressors but you’ll still want an accumulator to catch liquid coming back that could damage the compressors,” said Watters.

"The bottom line is that the premium we thought was going to exist to do DX ammonia really doesn’t exist.”

– Rick Watters, AMS Mechanical Systems

Ammonia DX technology is one of the low-charge scenarios that has emerged in the last few years in response to growing regulatory oversight of industrial facilities with more than 10,000 lbs. of ammonia. “Regulations and risk have driven interest in using ammonia and getting the benefits of it but using less of it,” said Bruce Nelson, president of Colmac Coil, also speaking at the Global Cold Chain Expo session.

Colmac has installed its ADX system at cold-storage and food processing plants in the U.S. Canada and Australia, said Nelson. In addition to Joliet Cold Storage and Liberty Cold Storage, end users include Shepherd’s Processed Eggs, Spanish Fork, Utah; Preferred Freezer Services, Richmond, Wash., US Cold Storage, Laredo, Tex., and Bidvest Tamworth, Tamworth, Australia.

In the Colmac ADX system, most of the ammonia comes out of the evaporator, explained Nelson. “It’s a 30-50 times charge reduction in the evaporator. That take out a lot of risk out of the occupied space and gets the overall charge well below 10,000 lbs.” It also reduces risk to the immediate neighborhood; the Joliet facility, for example, is located near residential houses.

Several technological advancements were required to enable the ADX system to reduce ammonia charge, such as “enhancements” inside the evaporator tubes. “We also use better distribution to get the ammonia to the right parts of the heat exchanger,” he said. “That’s the secret sauce.” Colmac also figured out the management and removal of water in pipes and vessels, he added. Both Joliet and Liberty plants use anhydrators to remove water,

A key benefit of the ADX system is its simplicity compared with a traditional ammonia system, noted Watters. “If a [traditional] ammonia system goes down, it takes a while to get back on line,” he said. “[The ADX system] is as simple as a light switch to turn off and on.”

Related stories