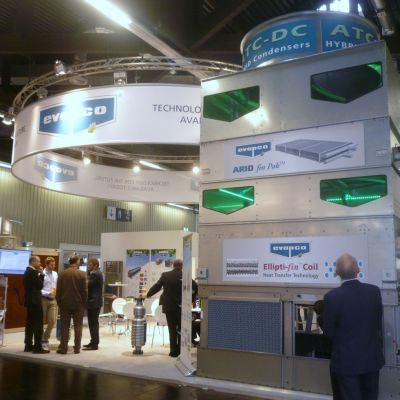

North American company EVAPCO, an industry leader in the engineering and manufacturing of industrial refrigeration system components, showcased its new ATC-DC wet dry condenser at Chillventa 2014. The ATC-DC significantly reduces water consumption utilizing the new ARID fin PakTM dry cooling coil. + PHOTOS

EVAPCO’s ATC-DC evaporative condenser is the latest example in Evapco’s on-going commitment to quality, innovation and environmentally friendly products. The ATC-DC is an induced draft, counterflow design evaporative condenser powered by innovative heat transfer and dry cooling coil technology.

Improved performance and significant water saving – key features of the ATC-DC evaporative condenser

Using the new ARID fin PakTM dry cooling coil, the ATC-DC achieves improved heat transfer during dry operation and significant water savings due to extended periods of dry operation.

The main features of ATC-DC evaporative condensers include:

Meeting customer needs: easy maintenance with additional options

While the design of the ATC-DC evaporative condenser is easy to maintainEVAPCO does offer a number of options to enhance access, performance and extend the life of the model. These include:

About EVAPCO

Founded in 1976 in Baltimore, EVAPCO has become a worldwide leader in the design and manufacture of industrial refrigeration system components. Company products can be shipped from any of the 19 manufacturing facilities in nine countries around the world. With an on-going commitment to Research, Development and Sustainable Technology, EVAPCO provides some of the most advanced products in the industry.

The company’s activities are focused on the following markets:

Improved performance and significant water saving – key features of the ATC-DC evaporative condenser

Using the new ARID fin PakTM dry cooling coil, the ATC-DC achieves improved heat transfer during dry operation and significant water savings due to extended periods of dry operation.

The main features of ATC-DC evaporative condensers include:

- Wet and dry (water consumption = 0) operation modes

- Ellipti-fin® cooling coil to assure even greater efficiency and water loading

- Pressurized water distribution system that offers full coil coverage and scale prevention and guarantees non-corrosion and maintenance-free water distribution system

- Superior air inlet louver and screen design minimizes splashout and reduces the potential for algae formation inside the cooler

- Efficient drift eliminator system that reduces entrained water droplets from the air discharge to less than 0.001% of the spray water flow rate

- POWER-BAND Drive System (5 years warranty)

- International Building code (IBC) Compliant

Meeting customer needs: easy maintenance with additional options

While the design of the ATC-DC evaporative condenser is easy to maintainEVAPCO does offer a number of options to enhance access, performance and extend the life of the model. These include:

- Sloped access ladders available for 8.5' and 12', (2,6 and 3,7m) wide ATC-DC models

- Stainless steel basin to maximize protection against corrosion (Type 304 or 316 stainless steel)

- Working Platform & Ladder with davit

- Electric water level control. Designed and manufactured exclusively by Evapco, it consists of multiple heavy duty stainless steel electrodes.

- Electric immersion heaters located in the basin of the condenser

- Remote sump configuration

- Four low sound solutions

- Pulse~Pure® water treatment system (Chemical free)

About EVAPCO

Founded in 1976 in Baltimore, EVAPCO has become a worldwide leader in the design and manufacture of industrial refrigeration system components. Company products can be shipped from any of the 19 manufacturing facilities in nine countries around the world. With an on-going commitment to Research, Development and Sustainable Technology, EVAPCO provides some of the most advanced products in the industry.

The company’s activities are focused on the following markets:

- Industrial Refrigeration

- District Energy

- Industrial Process

- Power

GALLERY

MORE INFORMATION

Related stories