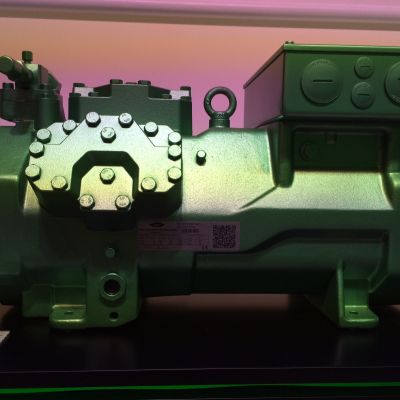

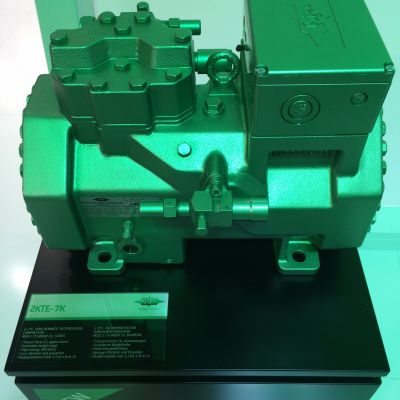

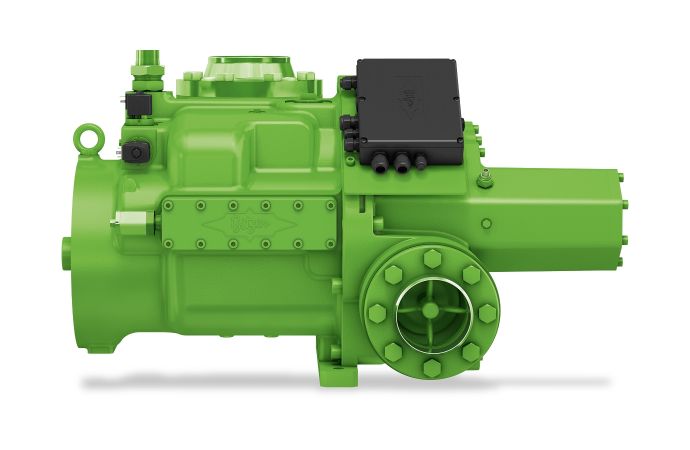

Those who were waiting to see BITZER’s new ammonia compressor - the OS.A95 series - were finally able to catch a glimpse at Chillventa 2014. Its impressive stats and trademark attention-grabbing green veneer got everyone who witnessed it talking, creating a palpable buzz over the newest addition to the BITZER family. Featuring smart electronics CM-SW-01 in combination with a Vi slider the compressor is suitable for a wide range of applications.

The new ammonia compressor -based on BITZER’s experienced OS.85 series - the OS.A95 is an expertly crafted compressor made for ammonia applications. But this isn’t the only difference, BITZER have also introduced a new integrated smart electronic board used in conjunction with a Vi slider and a newly developed horizontal oil separator which together ensure an impressive displacement rate of 1,015 m3/h at 2900 rpm.

Complete control due to new slider electronics

An instrumental part of the new OS.A95’s set-up is the integrated smart electronics CM-SW-01 that together with the Vi slider can be used to efficiently and infinitely adjust the volume ratio in a wide range of applications. The harmony between the two is so seamless that the electronics can accurately monitor the application limits, the allowable temperatures of the compressor and the oil supply.

The list of applications that the new model is able to service ranges from air-conditioning and medium temperature application to the low temperature refrigeration range. This versatility is due to the OS.A95’s enhanced rotor profiles, which possess optimised flow cross sections. The OS.A95’s infinite slider control with position indicator optimises compressor capacity adjustment in line with these system requirements, ensuring total efficiency each and every time. The internal oil management which stems from the CSH series is also employed to great effect, ensuring that only the really required quantities of oil is used to guarantee reliable and extremely efficient oil lubrication for the compressor even at low pressure differentials.

Slicker than ever- the new multistep oil separation operation

BITZER’s newly developed horizontal oil separator is made for the parallel applications of OS.A95 and OS.A85 as several separating stages can be combined in one vessel, making the system simpler and the units used minimal. BITZER crafted these steps with the goal of increasing the compressor capacity of the new OS.A95 series.

The other benefits of the OAHC65051A oil separator are:

BITZER’s new ammonia compressor and their other products went down a storm at Chillventa, with Volker Stamer, BITZER’s Director Stationary Products indicating his pleasure at the turn-out,

About BITZER

For 80 years, BITZER has been manufacturing refrigeration compressors, the “heart” of refrigeration and air conditioning systems. The company is considered a global leader in the production of screw, scroll and semi-hermetic reciprocating compressors for commercial air conditioning and refrigeration applications, with models specifically designed for natural refrigerants including ammonia. In addition to compressors, condensing units and pressure vessels are also part of BITZER’s product range, which is supplied around the world by more than 40 subsidiaries operating in 90 different countries on five continents.

Complete control due to new slider electronics

An instrumental part of the new OS.A95’s set-up is the integrated smart electronics CM-SW-01 that together with the Vi slider can be used to efficiently and infinitely adjust the volume ratio in a wide range of applications. The harmony between the two is so seamless that the electronics can accurately monitor the application limits, the allowable temperatures of the compressor and the oil supply.

The list of applications that the new model is able to service ranges from air-conditioning and medium temperature application to the low temperature refrigeration range. This versatility is due to the OS.A95’s enhanced rotor profiles, which possess optimised flow cross sections. The OS.A95’s infinite slider control with position indicator optimises compressor capacity adjustment in line with these system requirements, ensuring total efficiency each and every time. The internal oil management which stems from the CSH series is also employed to great effect, ensuring that only the really required quantities of oil is used to guarantee reliable and extremely efficient oil lubrication for the compressor even at low pressure differentials.

Slicker than ever- the new multistep oil separation operation

BITZER’s newly developed horizontal oil separator is made for the parallel applications of OS.A95 and OS.A85 as several separating stages can be combined in one vessel, making the system simpler and the units used minimal. BITZER crafted these steps with the goal of increasing the compressor capacity of the new OS.A95 series.

The other benefits of the OAHC65051A oil separator are:

- Optimised oil charge amounts

- A service flange for simple filter replacement

- Minimal oil carry-over rates, well below 10 ppm

BITZER’s new ammonia compressor and their other products went down a storm at Chillventa, with Volker Stamer, BITZER’s Director Stationary Products indicating his pleasure at the turn-out,

We’re happy that so many visitors showed an interest in our new products and our product portfolio as a whole, including our new BITZER OS.A95 ammonia compressors.”

About BITZER

For 80 years, BITZER has been manufacturing refrigeration compressors, the “heart” of refrigeration and air conditioning systems. The company is considered a global leader in the production of screw, scroll and semi-hermetic reciprocating compressors for commercial air conditioning and refrigeration applications, with models specifically designed for natural refrigerants including ammonia. In addition to compressors, condensing units and pressure vessels are also part of BITZER’s product range, which is supplied around the world by more than 40 subsidiaries operating in 90 different countries on five continents.

GALLERY

MORE INFORMATION

Related stories