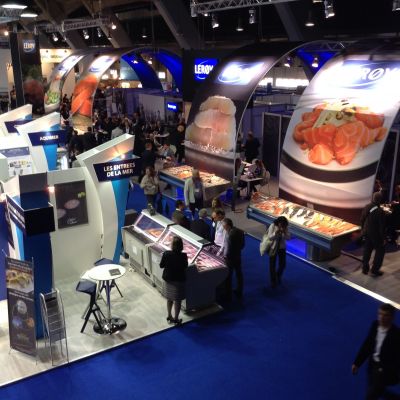

2014 marks the 16th Seafood Processing Global exhibition, organised alongside Seafood Expo Global, in Brussels Belgium from 6 -8 May. ammonia21.com reporters attended the trade fair, which is designed promote machinery and equipment relating to the fisheries industry, to discover new trends and technologies within the industry, using ammonia as the refrigerant. Several new companies featured alongside those reported on in 2013. + PHOTOS

Together, Seafood Expo Global and Seafood Processing Global make up the largest seafood trade fair, attracting over 1,690 exhibitors and 25,800 attendees. At this year’s event many of the exhibitors predicted the market for ammonia refrigeration and freezing technologies within the seafood sector would grow, as a result of the R22 ban, which means that as from 1 January 2015 the HCFC refrigerant will be prohibited in the European Union.

ammonia21.com partners exhibiting

- DSI: The Danish plate freezer manufacturer (bronze partner on ammonia21.com) displayed its continuous horizontal process freezers, designed for in-line process freezing of packed product in trays or cartons. The unique design offers instant freezing capability, and is made with a galvanised steal frame and hydraulic rams that ensure a stable and even plate pressure.

Other companies of interest exhibiting:

- Dalian Bingshan: at their booth the Chinese refrigeration system manufacturer promoted their ammonia refrigeration products for industrial seafood processing plants through posters and brochures. The company’s JZLG refrigeration screw compressor, compound two stage screw compressor unit, and single and double spiral freezers are all suitable for use with ammonia.

- Heinen: the German manufacture of spiral freezers displayed one of their arctic models. Suitable for use with ammonia, the spiral freezer can accommodate stainless steel or plastic belts, and different tier pitches, and is designed with fully welded stainless steel tray with defined drains. According to a company spokesperson, whilst keen to showcase their technology at the Seafood Processing trade fair, the bakery sector is also considered an interesting sector in terms of future market growth.

- MMC Kulde AS: With over 80 years experience in the refrigeration business, the Norwegian company have been providing ammonia RSW (refrigerated sea water) systems for fishing vessels since 2001. Recently the company launched a new range of compact, reduced ammonia charge chillers, the Optiflux RSW. The company also supplies and services vertical semi automatic plate freezer the PFV 44D, suitable for ammonia, and the KS E5 refrigerant pump.

- Optimar Iceland: The range of refrigerated seafood processing systems suitable for use with ammonia manufactured by the company include the Optiflux RSW, designed for cooling sea and fresh water, the KS E5 refrigerant pump, the PHF horizontal plate freezer, the PFV 4B vertical plate freezer, and the IQF tunnel freezer. Also manufactured is the Optim-Ice liquid ice system, which includes the BR -130 - refrigeration capacity 80kW/68.000 kcal/h, as well as ice storage tanks.

- Skaginn/ FROST: Since 1993, FROST has been servicing cooling and refrigeration systems for major players in the Icelandic fishing and food processing industry. Land-based projects the company is involved in range from small whitefish plants with a capacity of 20 – 50 tons in 24 hours, to some of the world’s largest pelagic plants with a 400 – 600 tons in 24 hour capacity, all refrigerated using ammonia. In recent years the company has installed a great number of GEA Grasso screw and piston compressors. The company works with Skanginn, who manufacture plate and IQF freezers suitable for use with ammonia.

GALLERY

MORE INFORMATION

Related stories