Transcritical chiller offers payback on 47% premium in a few years, says Zero Zone paper that compares CO2, NH3 and R448A.

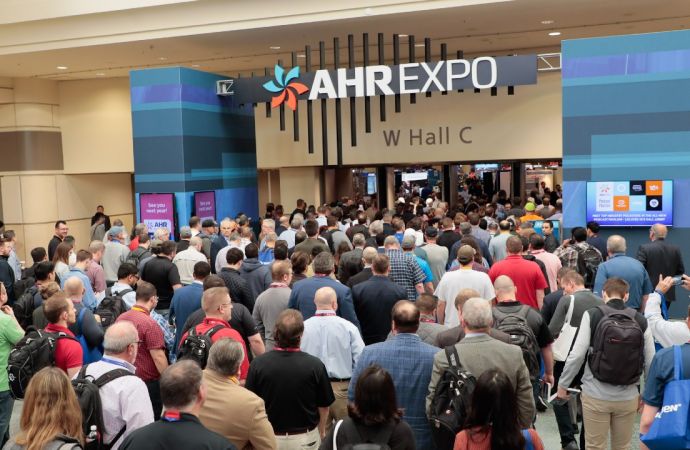

John Collins, Zero Zone, at IIAR's 2019 conference

In a study of packaged chiller systems used for ice rinks, a transcritical CO2 chiller was found to deliver a payback on its cost premium over a baseline system in “a few years,” based on13%-33% lower operating (electricity and water) costs.

The study – “Analysis of Package Chiller Systems – Comparison of Natural (NH3 and CO2) and HFC Refrigerants” – was conducted by John Collins, Industrial Sales Manager, Zero Zone, whose Refrigeration Division is based in Ramsey, Minnesota (U.S.). Collins was scheduled to present the study as a technical paper this week at the IIAR Natural Refrigeration Conference & Heavy Equipment Expo, but the event was cancelled due to the coronavirus pandemic.

The paper compares CO2 and NH3 chiller systems with two chillers using the HFO blend R448A; one of the R448A chillers employs evaporative condensing (the baseline system) and one is air-cooled. The chillers all use circulated glycol coolant. The nominal refrigeration capacity of the chillers is 160TR (562kW).

The energy analysis in the paper is based on “calculated performance” based on “readily available manufacturer data on component performance over the range of operating conditions,” the paper said. In particular, performance data was derived from “Bitzer compression selection software and other published equipment data on the heat exchangers and condensers/gas coolers,” Collins told this website.

The analysis of water consumption is based on a nominal 0.30 gal/TR-hr (0.32ltr/kW-hr) for the evaporative condenser systems ( baseline and ammonia), and one-quarter of this rate for the adiabatic gas cooler (in the CO2 system).

“This is a comparative analysis to show relative performance of the considered options across a range of operating conditions,” Collins said. “The performance data is not intended to serve as an annual or life cycle cost analysis.”

Cost comparison

While the costs of transcritical CO2 chillers are declining, the installed cost of the CO2system in the study was 47% higher than that of the baseline unit, the paper noted. The installed cost of the ammonia chiller was 67% above that of the baseline system.

The overall performance of the CO2 chiller, including energy and water usage, “allows for payback of the 47% premium in first cost over the baseline in just a few years,” the paper said. On the other hand, the 67% premium for the ammonia system “will take several years to make up.”

In the study, the chillers were evaluated based on climates in four U.S. cities, Minneapolis, Minnesota (cold northern climate); Philadelphia, Pennsylvania (mixed humid northern); Atlanta, Georgia (mixed humid southern); and Los Angeles, California (dry warm). They were analyzed at 100% load, 55% load and for seasonal operation (September-April).

The CO2 chiller employs parallel compression and adiabatic condensing, enabling it to “perform effectively at each of the locations considered over the entire range of annual weather conditions,” the paper said.

Compared to the baseline system, the CO2 chiller used less energy in the majority of the annual operating hours (62% of annual hours in Atlanta and 83% of annual hours in Minneapolis and Los Angeles). The added electric cost for the limited number of hours of peak hot weather operation “is more than offset by the savings during off-peak operation,” the paper said. Moreover, since the systems operate at reduced capacity much of the year, this “further improves the overall electric savings for CO2 over the baseline system.”

The electrical savings for the CO2 system, combined with much lower water use for the adiabatic gas cooler/condenser, “results in the total operating costs between 13% and 33% below baseline across the range of locations and conditions,” the paper said.

The electric use/cost of the ammonia system is the least for all the options, but the added cost of water for evaporative condensing “more than offsets the electric savings,” said the paper. “This is more pronounced in cooler climates and where water costs are high.”

This is a comparative analysis to show relative performance of the considered options across a range of operating conditions."

John Collins, Zero Zone

Related stories