Aquatics centers can cut their energy costs by replacing disparate heating and cooling systems with a water-to-water heat pump using a natural refrigerant

Electricity prices across much of Australia’s main grid hit record highs in the first quarter of 2019, according to data from AEMO, the Australian Energy Market Operator.

For local councils across Australia, which own energy-guzzling leisure and aquatics centers, this poses a problem. One solution may be an integrated energy system such as a water-to-water heat pump, which can dramatically reduce energy consumption.

“Water-to-water heat pumps are an almost perfect solution for aquatics centers,” said Derek Harbison, a renewable energy consultant at SmartConsult, at ATMOsphere Australia 2019, which took place o n May 8-9 in Melbourne, Australia. (The conference was organized by shecco, publisher of Accelerate Magazine.)

Harbison illustrated how these systems can significantly reduce energy use in aquatics centers during the conference’s policy and energy panel.

Water-to-water heat pumps often boast a coefficient of performance (COP) of up to 6.0, he said. Simultaneously adding the system’s cooling capacity adds another 5.0 for a total COP of up to 11. In addition, using natural refrigerants – CO2 or ammonia – in these systems contributes to superior energy efficiency performance compared to synthetic refrigerant-based counterparts, as well as providing low GWPs that protect against future regulations. Mayekawa is an example of a company that makes water-towater CO2 heat pumps.

Integrated energy systems that combine all the energy-consuming and energy-producing equipment into one package “fit very nicely into low-emissions regimes,” Harbison said.

Yet despite the heat pumps’ efficiency and environmental benefits, “it’s very difficult to convince councils to use them, because they are expensive,” Harbison said.

He has visited and evaluated aquatic centers in local councils throughout Australia ove r the past few years, making the case for the technology. He acknowledged that no installations have been completed yet.

One aquatics center used to account for 60% of a local council’s entire costs. “So when you sit in the room with these people, it’s a serious conversation – because people’s jobs are at stake,” he said.

Residents also take the facilities seriously. “People love their aquatic centers,” said Harbison. “They pay their rates, and they’re heavily subsidized by taxes.” This means that if visitors think the water or air is too hot or too cold, they are likely to complain. “Councils are under a lot of pressure to get this right.”

As we move towards a renewable energy supplied grid, we need to rethink our approach to high energy use in buildings.” - Derek Harbison, SmartConsult

Integrated Heating and Cooling

Illustrating the complex heating and cooling needs required, Harbison cited one facility where the pool water needs to be heated to 30°C (86°F), the pool air to 31°C (87.8°F), and the shower water to 55°C (131°F).

Meanwhile, there is also a significant demand for cooling – in the gym, cafeteria and office areas. The dry exercise areas need to be cooled to 19°C (66.2°F) and the office areas to 23°C (77.3°F). In the summer, cooling is also needed to maintain the pool air at 31°C (87.8°F).

“You also need to remove chlorinated air that is constantly evaporating off the surface of the pool, and eject all that heat from the building,” Harbison said. “This makes aquatic centers really hard to design,” he added.

It is here where a water-to-water heat pump would be an ideal solution, he said. The heat pump would have the ability to produce warm water at 40°C (104°F), hot water at 80°C (176°F), and cold water at 9°C (48.2°F). The hot and cold water would be circulated around the building via closed water loops.

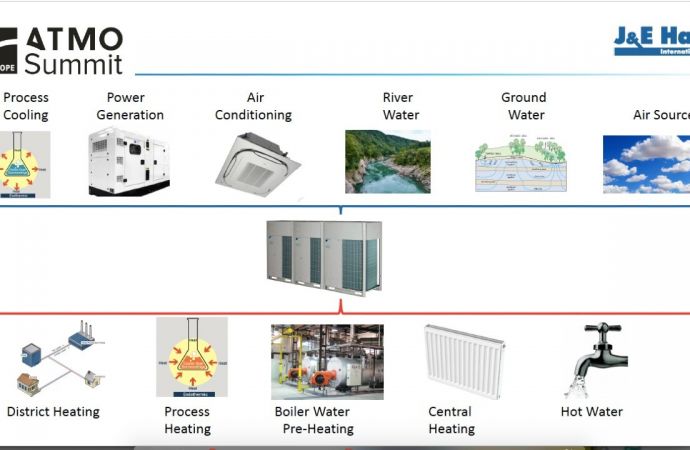

Heat pumps help customers to avoid what Scantec Managing Director Stefan Jensen calls “the unitary equipment disease,” whereby customers buy different pieces of equipment to serve different functions, such as air conditioning or heating hot water.

For example, one facility Harbison visited had different “bits and pieces of unitary equipment producing both hot and cold,” and whose efficiency performance varied considerably: gas boilers (0.85 COP), air-to-water heat pumps (3.8 COP), and a pool air-exchange unit (3.8 COP). “Sometimes they are all in the same room and you scratch your head thinking, ‘who designed this?'” he said.

By choosing a natural refrigerant-based water-to-water heat pump, he said, aquatics centers have the potential to save significant amounts of energy by using future-proof, integrated systems. “As we move towards a renewable energy-supplied grid, we need to rethink our approach to high energy use in buildings,” said Harbison.

Water-to-water heat pumps are an almost perfect solution for aquatics centers.” - Derek Harbison, SmartConsult

Related stories