Recently developed documents explain how to operate low-charge systems in compliance with the General Duty Clause.

Kurt Liebendorfer, Evapco

Last November, the International Institute of Ammonia Refrigeration (IIAR) released its first guidelines for users of low-charge ammonia systems that use a charge of 500 lbs. or less, but the trade group is open to suggestions on how the guidelines can be improved.

The guidelines, called Low Charge Ammonia Refrigeration Management (ARM-LC), are contained in two documents – a 13-page Summary and an 86-page Guidebook – that deal with safely installing, using and servicing low-charge ammonia systems in compliance with the General Duty Clause of the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA).

The Guidebook includes forms and templates in which manufacturers and contractors can provide end users with information on their low-charge ammonia installation. (Both documents can be purchased at IIAR’s website here: https://bit.ly/2UIcIJ9.)

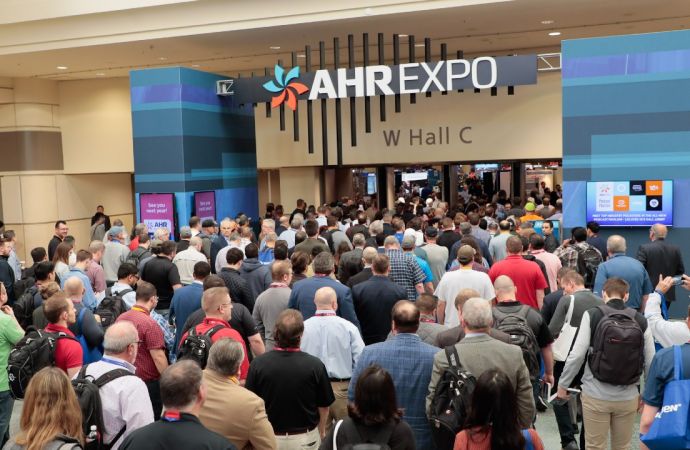

The guidelines, which covers packaged and stick-built low-charge ammonia systems, are designed to help to end users of low-charge systems that may have not used ammonia before or be familiar with the requirements of the General Duty Clause. and “need to have a reference document,” said Kurt Liebendorfer, vice-president of Evapco, in a presentation at the IIAR Natural Refrigeration Conference and Expo, held in Phoenix March 4-6.

“With this low-charge program we are just filling a void,” he said.

ARM-LC is a follow-up to IIAR’s ARM guidelines, issued in 2005 for ammonia systems using charges of between 500 and 10,000 lbs. Systems with more than 10,000 lbs of ammonia are subject to the more stringent regulations established by the OSHA and the EPA, known as Process Safety Management (PSM) and Risk Management Program (RMP), respectively.

ARM-LC generally covers systems with ammonia charge/capacity ratios of 0.5 lbs-7 lbs/TR; by contrast, large conventional ammonia systems have ratios of 20-30 lbs/TR or more.

One of the key messages of the guidelines is that low-charge systems reduce the level of regulations that ammonia operators face. However, “we know there is more peeling away of regulatory burden that can occur,” said Liebendorfer.

The IIAR’s Compliance Guideline Committee is therefore seeking input on ways the ARM-LC guidelines can be updated to reflect low-charge systems’ safety advantages, said Liebendorfer, a member of the committee.

For example, a leak of under 100 lbs of ammonia does not require an operator to notify an emergency response center. “But what additional layers of regulations could you remove?” he asked. “These are areas we want to explore with the next version of the program.”

In leaks from low-charge systems, there are typically no off-site consequences. “That has to be evaluated so we can determine how the program can be made easier for low-charge systems,” added Liebendorfer.

“Any input we would get back, we would try to incorporate into the workings of the committee and develop a revision of the document,” he said.

“With this low-charge program, we are just filling a void.”

– Kurt Liebendorfer, Evapco

Low-charge systems offer many operational advantages to end users, noted Liebendorfer. For example, unlike large ammonia systems, low-charge equipment allows end users to rely on manufacturers and contractors to provide safety guidelines and explain the day-to-day operation of a system.

Under the guidelines, contractors that install low-charge ammonia systems are responsible for training on-site employees, although the training would be significantly less intensive than for large, industrial facilities that use bigger ammonia charges.

For packaged systems, the ATM-LC guidelines suggest that manufacturers should conduct a hazard review before the equipment is installed, rather than the full-scale process hazard analysis (PHA) that would normally be conducted at facilities with large ammonia systems.

Packaged ammonia systems are typically pre-engineered with strong quality control. Moreover, an owner of a low-charge system can treat it as personal property, which can also translate into big tax savings, said Liebendorfer. “And they have a lower life cycle costs.”

The ARM-LC guidelines recommend that end users amend their existing emergency response program with instructions on how to respond to the smell of ammonia. It should trigger a call to the contractor, and could include an evacuation plan.

Packaged low-charge ammonia refrigeration and chiller systems are being produced by a growing number of U.S. manufacturers, including Azane (a division of U.K-based Star Refrigeration Group), Mayekawa and Evapco. “There are a lot of package providers out there that are bringing these low charge systems to market,” Liebendorfer said. “IIAR didn't want to fall behind in establishing guidelines and creating expectations for these systems.”

The low-charge units are being used in a wide range of applications, including data centers, manufacturing facilities and ice rinks. They are also being employed in places outside the core market for ammonia refrigeration, such as small distribution centers, food-preparation facilities and supermarkets, where a handful of stores are testing ammonia/CO2 cascade systems, he noted.

The ARM-LC guidelines are designed to help the latter end users, who typically don’t employ technicians on site and where a service contractor business model is the general practice

The guidelines contain information on operating and maintenance procedures. “So if a leak occurs, you have a methodology to investigate it,” Liebendorfer explained. They also provide a qualification program for contractors so that in the event of an emergency “you have the basis for an action plan.”

IIAR does not plan to incorporate the guidelines into IIAR codes and standards. However, the latest version of IIAR’s safety standard, IIAR-2, includes a chapter on ammonia packaged systems. “IIAR wants to expand on that,” he added.

Related stories