The Australian firm recently commissioned two new projects for industrial applications in Melbourne and Brisbane.

Scantec’s recently commissioned low-charge ammonia ScanPAC system, Melbourne

Photo credit: Marty Pouwelse

Accelerate Australia & NZ spoke to Stefan Jensen, managing director of Scantec – a leading Australian supplier of low-charge ammonia systems – about two new industrial projects, in Melbourne and Brisbane. Jensen argues that low-charge NH3 systems can deliver 3-4 times as much cooling capacity per kilogram of charge than liquid overfeed systems.

“We recently commissioned our new low-charge NH3 ScanPAC in Melbourne; this has an alcove evaporator with automatic ambient air defrost,” says Jensen.

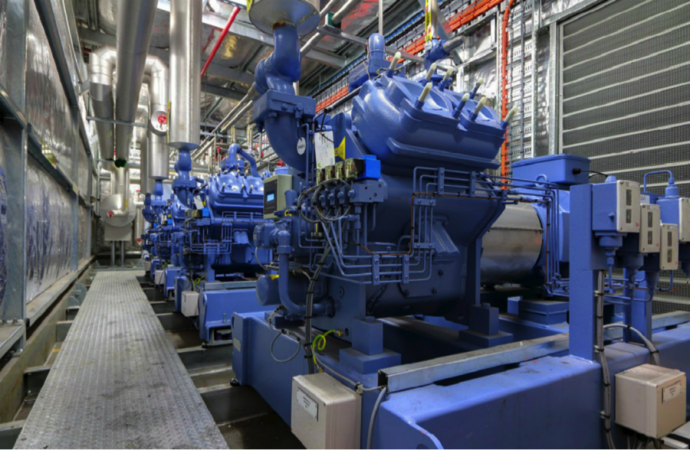

The Brisbane project, for a Japanese end user, was recently completed under significant time pressure, the Scantec boss reveals. The end user relocated from other premises to meet growing demand for its product and was after a premium system.

“In Brisbane, the first stage compressors operate at -27°C saturated suction temperature, and the corresponding freezer store temperature is -22°C. This particular plant employs Japanese compressors and custom-engineered evaporators with special circuiting and distributors from a German manufacturer,” Jensen says.

Benefits of low-charge ammonia

He is quick to point to the various benefits of low-charge systems compared to industry standard HFC-based systems, and for good reason. “The only feedback from the end user we’ve had is happiness.”

“The initial capital investment differential between an industry-standard HFC-based, single-stage compression system (with air-cooled condensers and electric defrost) and a state-of-the-art, low-charge NH3 system is usually returned in three years,” Jensen says.

“The documented annual energy consumption difference between the two scenarios described above is 40 to 67%, depending on the circumstances, with the low-charge NH3 system being the best performing,” he reveals.

Jensen was discreet on confidential new projects but mentioned three more low-charge systems currently under construction in Sydney, Brisbane, and Dongguan in China.

Innovation by Scantec

Scantec sees a significant role for ammonia if manufacturers can persuade end users of the greater long-term energy efficiency and cost gains available.

What sets Scantec’s systems apart is that instead of pumping the refrigerant around, they utilise the normal pressure differences in the system – between condensing and evaporating pressure – to facilitate the process. “We’ve redesigned the way the evaporators are circuited, we have refined the way the temperature, pressure and quality sensors are positioned, and we have paid particular attention to the thermal conductivities of the evaporator materials,” Jensen says.

Scantec has also developed a new control system that modulates injection into the evaporators. The control methodology relies on a combination of super-heat signal and quality signal at the evaporator exit. “We believe this control principle can be applied very broadly and very cheaply to a range of applications, including air conditioning. It’s simply a matter of numbers to get the price down,” Jensen says.

The initial capital investment differential between an industry-standard HFC-based, single-stage compression system and a state-of-the-art low charge NH3 system is usually returned in three years.”

- Scantec Managing Director Stefan Jensen

Growing popularity of industrial ammonia systems

It’s no surprise that low-charge ammonia technology is also gaining popularity around the globe due to updated regulatory guidelines.

In the US, for example, a growing number of industrial refrigeration end users are installing packaged low-charge ammonia units, in a major break from traditional refrigeration technology.

The NXTCOLD low-charge packaged ammonia refrigeration system has already been installed in several big cold storage facilities like LA Cold Storage, Lineage Logistics, Baker Cold Storage and Neptune Foods.

The beauty of the technology is that low-charge NH3 systems can be applied in much smaller applications than conventional NH3 ‘liquid overfeed’ systems, typically used in semi-industrial applications of 30-50 kW and above.

To read the complete article 'Spotlight on Australia: Innovations shaping change in 2017' in the summer issue of Accelerate Australia NZ magazine, click here .

Related stories